ZEDsystem

Standardized

leak testing 2.0

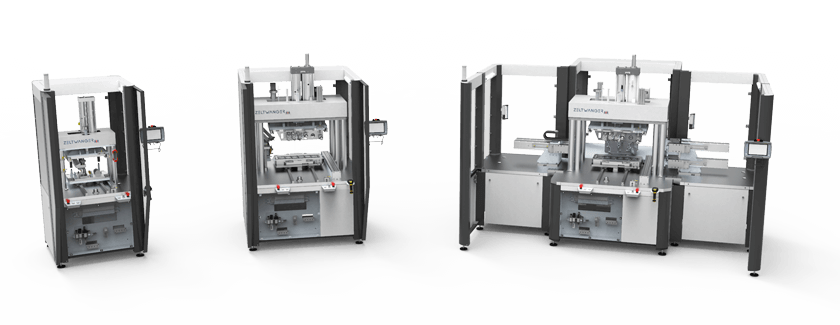

ZEDsystem is an individually configurable sliding table system for leak testing.

It allows additional processes to be integrated, fast changeover, and manual or automatic loading. ZEDsystem can be integrated into fully automated production lines or used manually and three choices of series offer the perfect solution for any customer requirement.

Measuring methods

RD | RD relative pressure (optional: 2-channel) |

RD / GP | relative pressure with bell testing |

RD / DF | relative pressure with flow rate |

DD | differential pressure |

SD | accumulation pressure |

MF | mass flow |

(Pressure ranges: See ZEDcore, ZEDsatellite)

Additional processes

- Component marking using lasers (DMC code), scoring, punch marking, or color dot marking

- Joining

- Pressing balls / expanders

- Screwing

- Electrical test

- Presence monitoring

- Barcode / DMC scanning

ZEDsystem application examples

- Automotive: Aluminum cast housing, cylinder blocks, cylinder heads, gears, heat exchangers, electronic control units, batteries, lines, valves, fuel cells, pumps, etc.

- Medical technology: Catheters, dialysis filters/boxes, flushing/hose systems, secretion containers, syringes, external lung machines, etc.

- Packaging/cosmetics: Dispensing pumps, plastic bottles, cartridges, etc.

- Household appliances: Water switches/pumps, gas valves/fittings, electrical components, etc.

- General industry: Cylinders, safety/non-return valves, couplings, grippers, ball valves, seals, etc.

ZEDsystem: Overview of the series

Product features

- Control unit: Siemens or Beckhoff

- Control elements: Multi-touch mobile panel and control panel

- Communication: Connection to customer ERP systems via OPC UA, TCP/IP, SAP, master computer, … or USB and network interface, e.g. for file export in CSV, XML

- Security: Lateral enclosure, swing doors with safety switches at the rear, accessibility at the front through safety light grid, safety-related connection to automatic loading and unloading

- Pneumatics / electrics: Integrated in the system

- Status display: System status via signal light, component testing IO/NIO via LED concept

- Interchangeable tools: Coded quick-change system (RFID, binary), changeable from front and back, tool-free

- Efficient: Reduced consumption due to intelligent software, modern components, and correct dimensioning

| Series | 1000 | 2000 | 3000 |

|---|---|---|---|

| Minimum component size (L x W x H) | 350 x 350 x 250 mm | 600 x 500 x 300 mm | 600 x 500 x 300 mm |

| Max. component weight | 25 kg | 50 kg | 50 kg |

| Max. adaptation forces | < 30 kN /< 5 kN (vert. / horiz.) | < 100 kN /< 15 kN (vert. / horiz.) | < 100 kN /< 15 kN (vert. / horiz.) |

| Cycle time | approx. 8 s (plus test time) | approx. 10 s (plus test time) | approx. 12 s (plus test time) |

| System dimensions (L x W x H) | 1,100 x 1,100 x 2,200 mm | 1,540 x 1,540 x 2,200 mm | 3,740 x 2,640 x 2,200 mm |

| Number of leak testing modules | up to 3 (max. 6 channels) | up to 4 (max. 8 channels) | up to 4 (max. 8 channels) |

| Power supply | 400 V | 400 V | 400 V |

All technical information is available to download on the data sheet.

Related products

- Customer service

- +49 7072 92897-572

- support.au@zeltwanger.de

- Sales

- +49 7072 92897-524

- Backoffice.lta@zeltwanger.de

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de