Zeltwanger Leak Testing & Automation

German engineering skill meets American ingenuity

At ZELTWANGER Leak Testing & Automation, we bring German expertise in leak testing, smart laser cells, and automation to the US.

We provide expert advice, offer advanced technology solutions, and develop individual concepts to meet your specific needs.

We can do it ALL: Automation, Lasers, Leak testing –

our key areas of expertise are laser machining and leak testing processes as well as the automation involved in these processes. We develop state-of-the-art solutions that meet the requirements of a wide variety of industries.

With our headquarters based in Charleston, South Carolina, we are your partner in North America.

Integrate our technologically advanced leak testing devices yourself or leave it to us as a one-stop-shop provider with the necessary expertise for manual workstations or fully automatic cells. These can be operated independently or integrated into your production lines.

Lasers and leak testing – two core processes that are increasingly required in e-mobility and medical technology.

Our range of services:

Automation, laser applications, and leak testing

At ZELTWANGER Leak Testing & Automation, we offer innovative production systems with various options for process integration.

Get in touch to find out more about ZELTWANGER Leak Testing & Automation.

Focus on automation

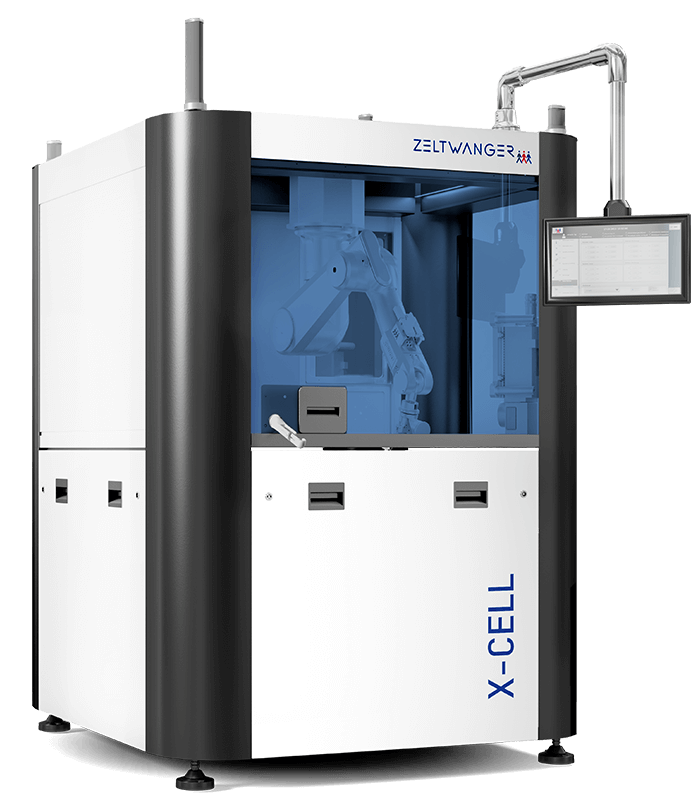

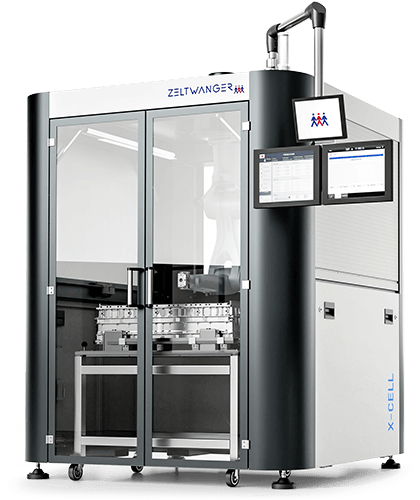

All-in-one with the automated X-CELL

Integration of laser technologies is our area of expertise. This includes welding, labeling, cutting, marking, and other applications. We use our knowledge to integrate other processes in addition to lasers – if possible, in the same system. Whether it’s screwing, assembling, or testing – we are leaders when it comes to combining important processes.

Scalable factory

Incremental investment

Space-optimized

Redundant/back-up

X-CELL LRA: Laser robot applications

The X-CELL LRA is our scalable and modular standardized machining cell that facilitates a variety of automated processes – everything in one system. It is particularly geared towards assembly processes, laser applications, and test procedures for quality assurance.

The advantages go beyond the laser and light-resistant housing. Multiple X-CELLs can be linked together or scaled cell by cell so that the processes can be adjusted step by step according to demand and increasing production quantities.

X-CELL MED: Fully automated laser system

The fully automated system can mark medical devices, instruments, and packaging easily and completely safely (laser marking, black marking, annealing). This can help you to comply with UDI marking requirements and the requirements of HIBCC, GS1, and ISBT.

Various configuration options give manufacturers in medical technology plenty of free reign in order to adapt the technology to their conditions.

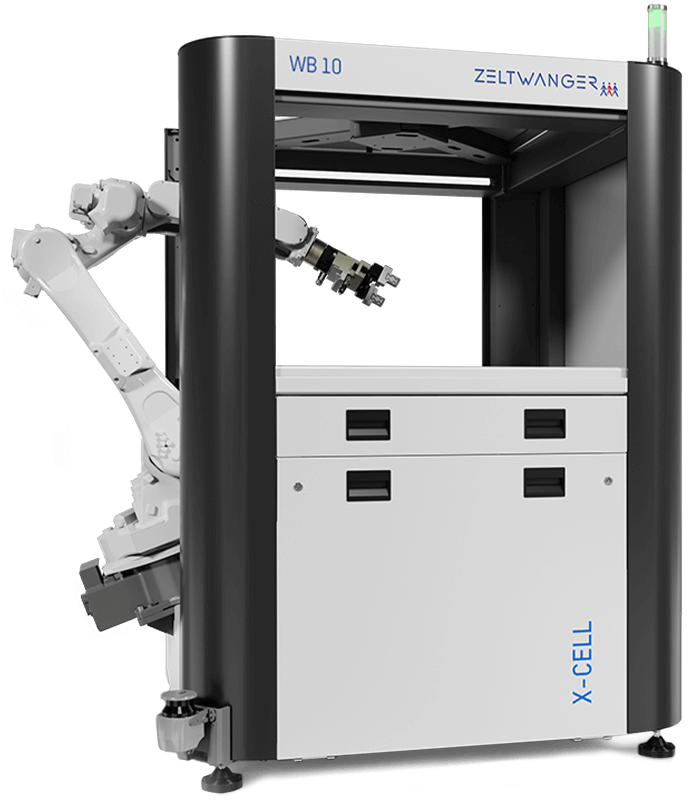

X-CELL WB: Machine tool loading

With this version of the X-CELL, we have developed a platform for the automatic loading of your CNC machines.

Discover more about the advantages of truly intelligent machine tool loading without any robot programming knowledge and find out more about the unique selling points of the X-CELL WB.

Other automation platforms

We also have experience with in-line, one-piece flow, or revolving systems which are incorporated into our new platform to produce fuel cells.

Get in touch for advice on finding the right automated solution.

Focus on laser technology

The integration of different laser technologies is one of our core strengths. We are building on many years of experience in this area in our company.

With the X-CELL, ZELTWANGER has developed a solution concept for the integration of various laser processes: Welding, labeling, ablation, engraving, black marking, cutting, cleaning, etc. – all these processes can be automatically integrated into production workflows in line with customer requirements.

We look closely at your requirements and production workflows and then plan successful and economically optimal laser automation concepts together with you.

To achieve this, we work with the world’s leading laser manufacturers.

By loading this video, you accept the YouTube Privacy Policy.

Find out more

Focus on leak testing

Leak tightness is essential in many industries in order to guarantee seamless component and product operation. Successfully testing for leaks and identifying possible leaks at an early stage is crucial for the success and reputation of a company.

By loading this video, you accept the YouTube Privacy Policy.

Find out more

We support you

Because leak testing processes are complex, we don’t just sell generic leak testing devices. We plan and implement overall concepts that are based on the requirements of our customers. We are helping you to take leak tightness to a whole other level with a new device series with many unique features.

We start all processes by analyzing feasibility and parameters, then planning preliminary tests and adaptations, and finally passing on all the necessary expertise onto you in training courses and workshops.

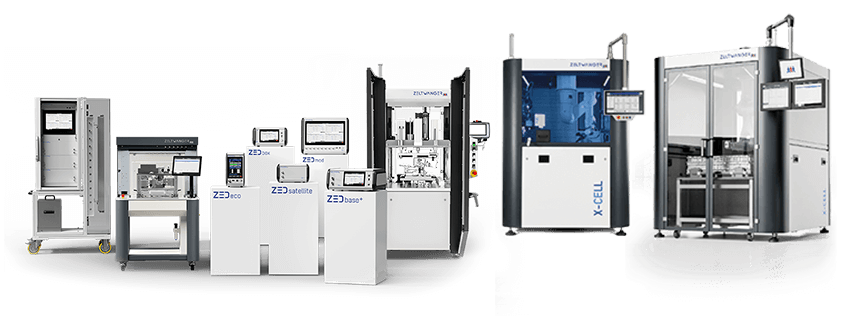

Flexible leak testing processes with the ZED family

Alongside our extraordinary process knowledge, our highly modern devices play a major role in the success of our leak testing concepts. The ZED device family offers standardized, adaptable solutions for a wide range of requirements.

We are the only provider worldwide that has designed a modular measuring concept. With the ZEDcore plug-and-play measuring module, our air leak testing meets the highest industrial requirements because you can exchange our measuring module yourself in just one minute for upcoming calibrations or any repairs.

Only ZELTWANGER offers you a network of all devices with the Internet of Things (Industry 4.0) via our standard OPC UA interface.

When you need to be more precise: Leak testing with detection gases

The ZEDcell is our standardized, robot-controlled system which you can use to locate even the smallest leaks with detection gases using the sniffer method. This can be used, for example, to locate leaks in battery packs for electric cars with the highest accuracy.

ZELTWANGER LTA – our expertise

Our expertise results from the fruitful combination of German engineering, American ingenuity, and a high level of customer focus. Our work is characterized by technical expertise and our passion for developing ideas for future challenges. That is why we can guarantee the best possible solutions and keep our promises to our customers.

It is important to us to do more than just talk about our expertise. That is why we have had ourselves certified according to globally applicable standards such as ISO 9001. You can download the certificate here:

We are there for you

ZELTWANGER LTA

We support you throughout the whole process as a partner, from planning through to commissioning and maintenance. Get in touch so we can help you further.

Markus Esslinger

Customer service/After Sales

ZELTWANGER Leak Testing & Automation

+1 (843) 225-0571

support.lta@zeltwanger.com

Dominic Hofer

Industry Management Medtech

ZELTWANGER Leak Testing & Automation

+49 7072 92897-528

medical-technology@zeltwanger.de

Ryan Takacs

Sales Automotive & E-Mobility

ZELTWANGER Leak Testing & Automation

+1 (248) 504-7013

contact.lta@zeltwanger.com

- Dominic Hofer

- Industry Management Medtech

- +49 7072 92897-528

- medical-technology@zeltwanger.de

- Ryan Takacs

- Sales Automotive & E-Mobility

- +1 (248) 504-7013

- contact.lta@zeltwanger.com

- Markus Esslinger

- Customer service/After Sales

- +1 (843) 225-0571

- support.lta@zeltwanger.com

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de