ZELTWANGER Fin Mill

THE FUTURE OF HEAT EXCHANGER PRODUCTION

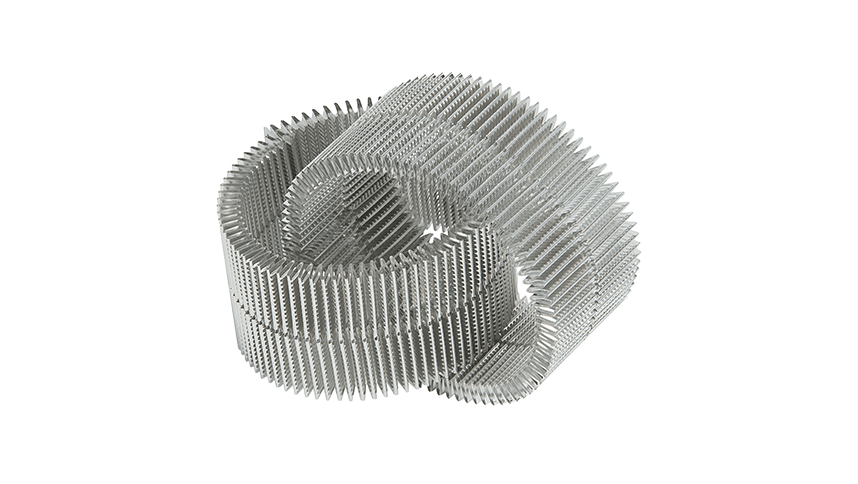

Highly efficient heat exchanger fins are the core components of high-performance heat exchangers. Intelligent and pre-designed systems based on standardized processes and architectures are key to producing a high-performance fin mill.

- Home

- Technologies

- Thermal management

- ZELTWANGER Fin Mill

OUR SOLUTION FOR TECHNICALLY SUPERIOR

HEAT EXCHANGER PRODUCTION

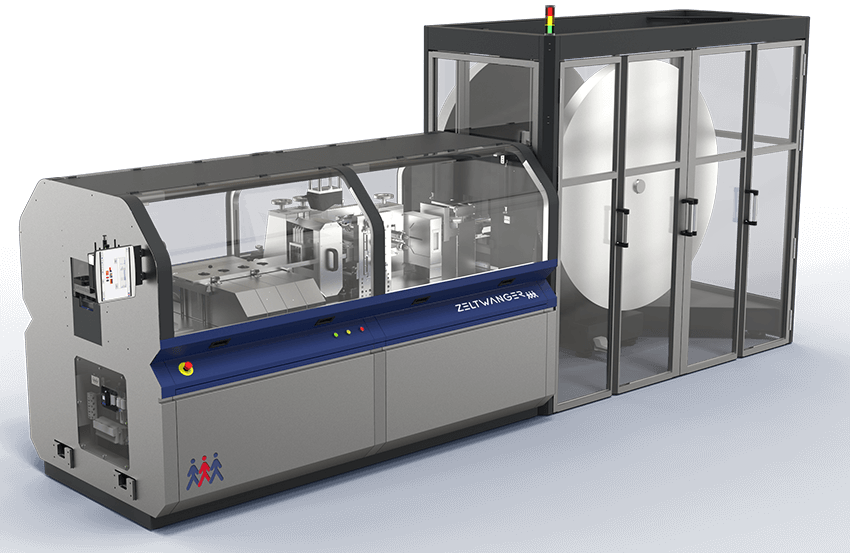

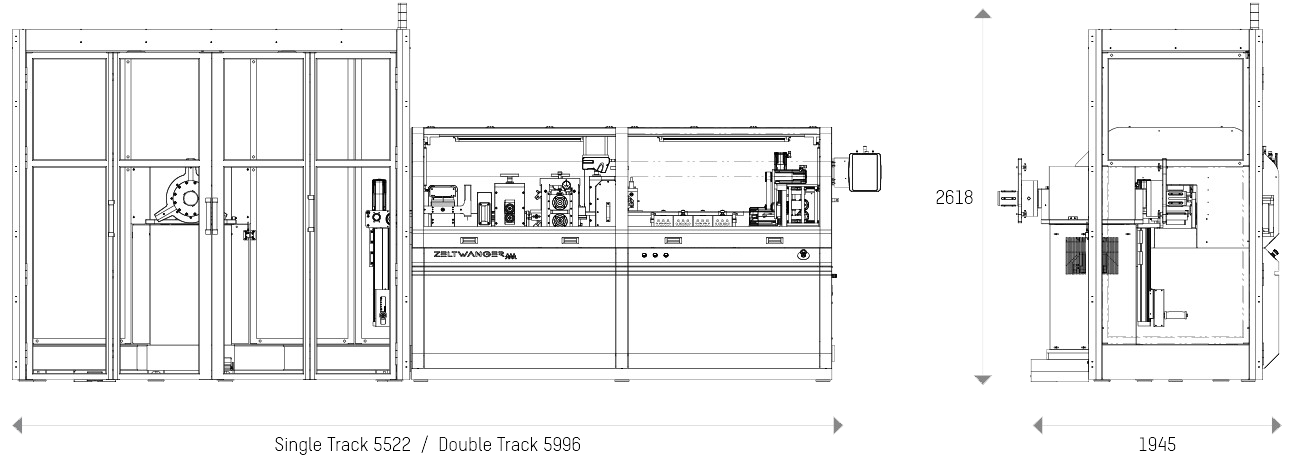

Requirements for complex fin geometries and extremely high fin densities are met thanks to the high-precision fin production system. Ranging from corrugated fins right the way up to oil cooler fins, a wide variety of fin types can be produced. The production process achieves a fin height accuracy of ± 0.01 mm at speeds of up to 6.5 m/s. Performance can be increased by using the double-track system.

A further advantage of the machine is its compact size, as the control cabinet is integrated in the machine’s base frame. Overall, the footprint of our fin mill is 50% smaller than other machines available on the market.

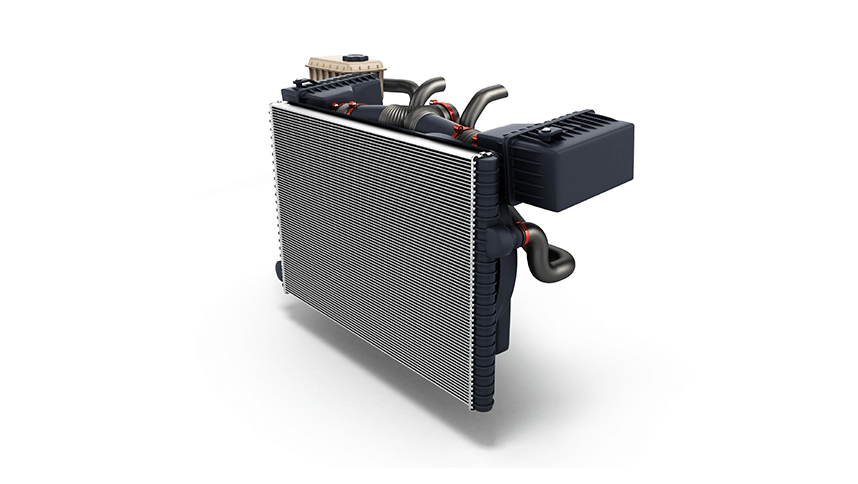

AREAS OF APPLICATION

-

Low-temperature coolers

-

Condensers

-

Evaporators

-

Coolant coolers

-

Radiators

-

Heat pumps

-

Intercoolers

-

PTC heaters

TECHNICAL DATA AT A GLANCE

| Layout | Single track & double track |

| Fin type | Louver fins, flat fins, oil cooler fins, turbulator fins |

| Strip material | Aluminum, stainless steel, copper |

| Strip width | 10 mm – 110 mm |

| Fins/min | 180 fins/min (single track) / 360 fins/min (double track) |

| Conveyor speed | Max. 6.5 m/s |

| Changeover time | Max. 10 min with one fitter |

Requirements for complex fin geometries and extremely high fin densities are met thanks to the high-precision fin production system. Ranging from corrugated fins right the way up to oil cooler fins, a wide variety of fin types can be produced. The production process achieves a fin height accuracy of ± 0.01 mm at speeds of up to 6.5 m/s. Performance can be increased by using the double-track system.

A further advantage of the machine is its compact size. The control cabinet is integrated in the machine’s base frame. Overall, the footprint of the ZELTWANGER fin mill is 50% smaller than other machines available on the market.

THE ADVANTAGES OF OUR FIN MILL

-

Compact design with integrated control cabinet

Stand-alone system, requires 50 % less space -

All process settings are controlled via the HMI

No manual operator settings required -

Guillotine provides horizontal flying cut

No start/stop and no variations in length -

Highly dynamic cutting unit

180 cuts per minute, single track with high fin density -

Automatic coil strip edge control

Accuracy of ± 0.05 mm at 6.5 m/s

-

Oil lubrication based on speed and spray width

Optimized oil consumption -

Inline height and density measurement system

100 % quality inspection -

Integrated fin angle measurement system

Maximum quality assurance -

Variable production direction

Maximum flexibility -

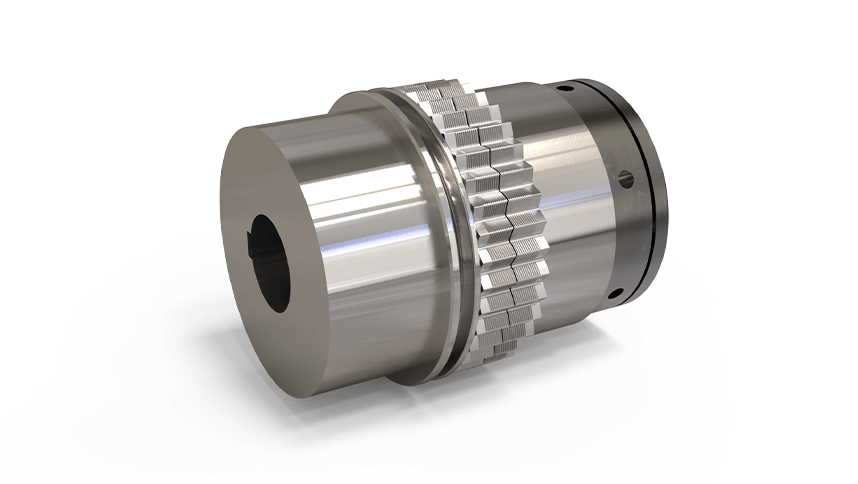

Manufacturer-independent form roll holder

Maximum flexibility for tool selection

POSSIBLE APPLICATIONS

Fin form roll

Thermal management

Corrugated fins

Heat exchangers

A summary of all the information on the fin mill:

USPs & Benefits

-

Double-head decoiler

Tool-less strip width adjustment

> Setup times reduced by 50 % -

Tension controller

Slip-free control

> For uniform corrugated fin height -

Web edge control

Angle compensation of up to ± 5°

> Maximum flexibility

-

Rotary shears

No change parts required

> Setup is omitted completely -

Form roll

Quick tensioning system

> Setup times reduced by 80 % -

Gathering roller

Type change via gathering disk pack

> Reduces setup times to a minimum

HIGH-END HEAT EXCHANGER PRODUCTION

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWE ARE HAPPY TO ASSIST YOU!

Do you have any questions about our mill? Our highly trained team will be delighted to provide you with information and advice.

Wladimir Leimann

Division Manager

ZELTWANGER Thermomanagement

+49 7072 92897-229

thermomanagement@zeltwanger.de

- Wladimir Leimann

- Division Manager

- +49 7072 92897-229

- thermomanagement@zeltwanger.de

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de