Leak testing with detection gases such as helium

Find the smallest leaks

Non-toxic, odorless, and easy to trace – the noble gas helium has numerous advantages. This is why we have developed comprehensive and needs-based testing concepts using helium and other detection gases.

- Home

- Technologies

- Leak testing

- Leak testing with detection gases

Helium only occurs in the ambient air in low concentrations and does not react with other gases. It can also be used regardless of temperature and volume changes.

The result: Quick tests in which even the smallest leaks are detected are possible. ZELTWANGER has expanded its expertise in this area and, with the ZEDcell and ZEDdetect, offers comprehensive, adaptable test systems for detection gas testing.

ZEDcell – the system for leak testing with detection gases

ZELTWANGER sees itself as more than a supplier of leak testing systems – it is a complete system partner that is constantly monitoring changing quality assurance requirements.

This is why we have developed the ZEDcell, a standardized, robot-controlled system which you can use to locate even the smallest leaks using the sniffer method. It can be easily adapted to your needs and integrated into your production lines.

The advantages of the ZEDcell

-

Sniffer testing method

-

Minimal leak rates, high repeat accuracy

-

Reproducibility

-

Design, technology, automation, and assembly from a single source

-

Easy calibration

ZEDdetect – vacuum test and accumulation method

With the ZEDdetect, we have developed a modular system for the vacuum and accumulation testing method. We configure the test chamber according to your requirements or the test method.

The advantages of the ZEDdetect

-

Vacuum and accumulation testing method

-

Standardized process and control technology

-

Scalability according to the size of the test object

-

Manual and automated loading

-

Flexible customer connection thanks to OPC UA

If you are looking for a system for leak testing with detection gases, please get in touch with our service team. We are happy to offer competent advice.

Test method with detection gases like helium

Depending on the application environment and requirements, three leak testing methods with detection gases, such as helium or hydrogen, are particularly suitable: The sniffer test, the accumulation test, and the integral vacuum test.

Here are the methods in more detail:

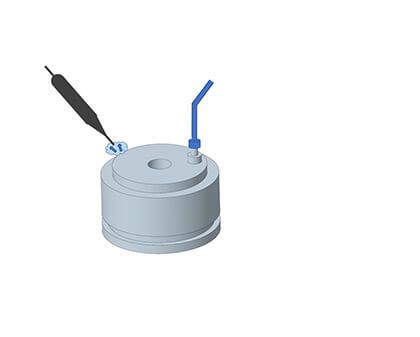

Sniffer testing

Application: For leak localization

The test object is pressurized using tracer gas. The sniffer probe is then guided around the part. In the event of a leak, the leak detector will identify the escaping tracer gas and locate the leak.

- Localization of the leak

- As a rule, the object to be tested does not have to be evacuated – or at least not completely

- Easy to do

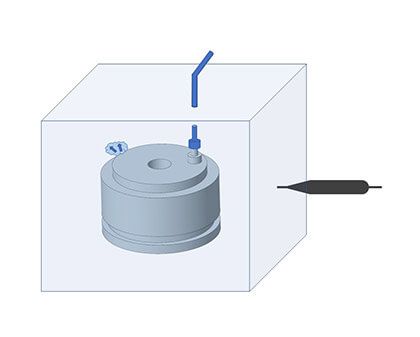

Accumulation test

Application: The test object must be tested as a complete product.

The test object is filled with tracer gas in a simple collecting chamber, which subject to atmospheric pressure. After an accumulation time, the detector analyzes the air in the chamber and determines whether it is possible to measure an increase in the tracer gas concentration.

- Easy to integrate into the production line

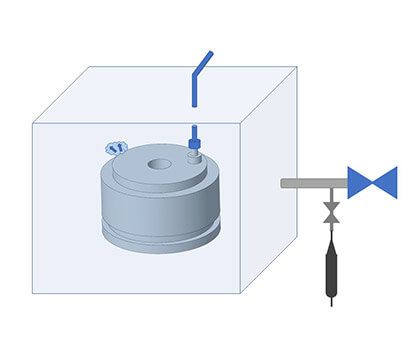

Integral vacuum test

Application: In production environments

The test object is place in a vacuum test chamber and filled with tracer gas. If a leak is present, tracer gas will leak from the test object in the test chamber and be measured by the leak detector.

- Very sensitive

- Easy to integrate into the production line

- Easy to calibrate

- High repeat accuracy

The leakage rates from individual tests demonstrate the precision of the method.

Still have questions?

Leak testing with air

Service

If you have questions about our systems and processes, please contact our service team.

- Customer service

- +49 7072 92897-572

- support.au@zeltwanger.de

- Sales

- +49 7072 92897-524

- Backoffice.lta@zeltwanger.de

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de