-

PASSIONATE TECHNOLOGY INNOVATORS

PASSIONATE TECHNOLOGY INNOVATORSWith high-tech mechanical engineering and cutting-edge testing technology, we assist our customers in creating superior products.

-

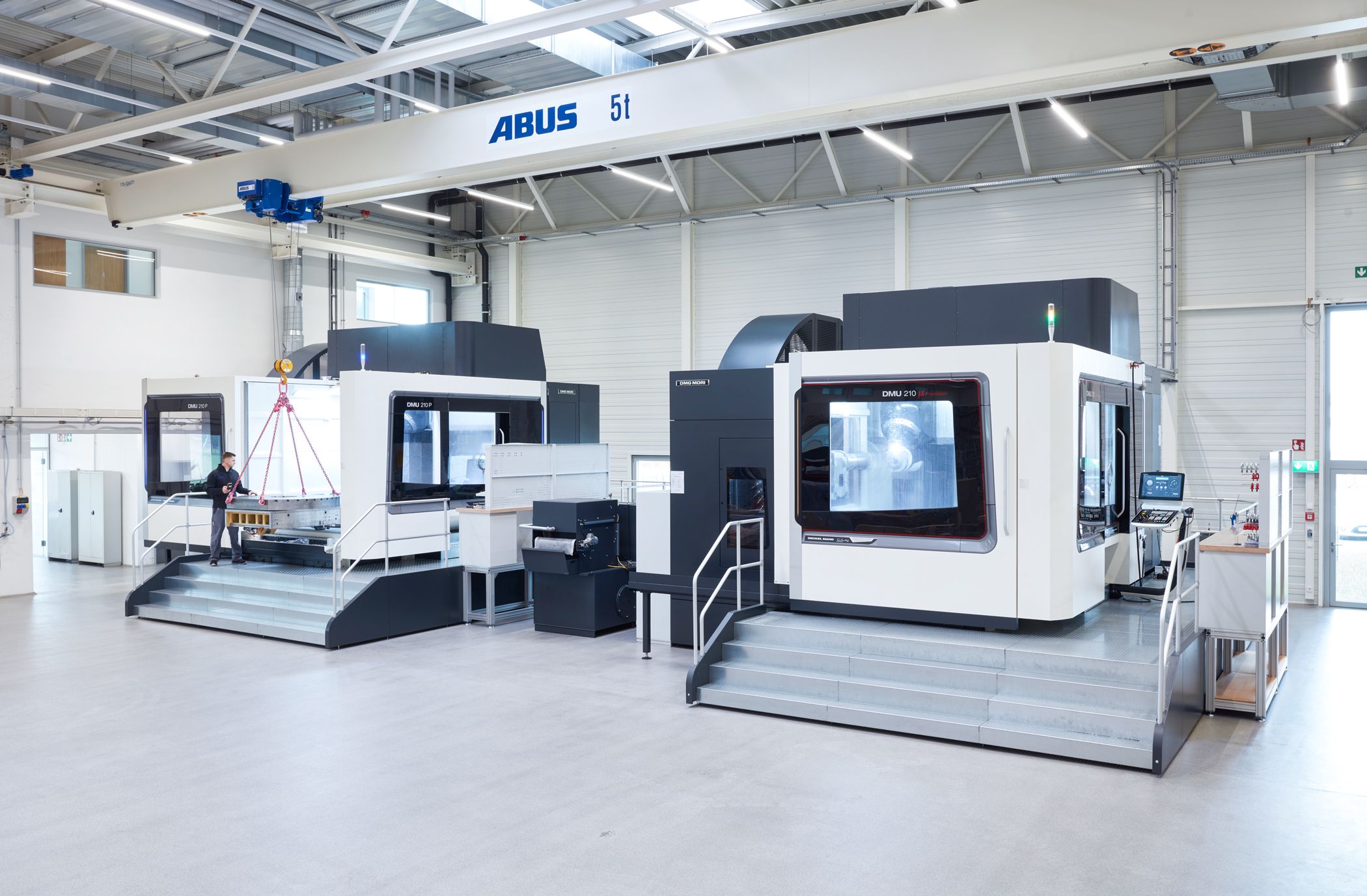

Contract manufacturing

Contract manufacturingWhether it be ready-to-install individual parts, complex prototypes, modules or complete systems – we implement your mechanical engineering projects reliably and efficiently

-

Leak TestingComprehensive leak testing from a single source: devices, automation, software, adaptation and service

Leak TestingComprehensive leak testing from a single source: devices, automation, software, adaptation and service -

thermal managementFrom fin to the block: efficient systems for the production and functional testing of modern heat exchangers

thermal managementFrom fin to the block: efficient systems for the production and functional testing of modern heat exchangers

ZELTWANGER

FROM A PASSION FOR TECHNOLOGY

We create excellent solutions to make your production even more efficient and sustainable –

with passion, expertise and foresight.

Our products: configurable and flexible

State-of-the-art, standardised and developed as a solution for the challenges faced by our customers: introducing our adaptable devices, systems and services.

WE NEED PEOPLE WITH PASSION!

Do you enjoy contributing your passion, knowledge and experience to help shape a more sustainable future? Do you use freedom responsibly to implement ideas, with a love for important details? Benefit from the advantages of a future-orientated family business in the mechanical engineering and technology industry.

PARTNERSHIP IS OUR TOP PRIORITY

Eight companies,

six locations,

one goal

Mechanical engineering, leak testing, and thermal management – driven by a passion for technology, we rank among the technology and innovation leaders in our areas of expertise. Applying our strengths, we aim to shape the world of manufacturing in a future-proof and efficient manner.

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de