State-of-the-art machines

Well-equipped for the technologies of tomorrow: ZELTWANGER is investing 6.2 million in state-of-the-art machines.

More space, more employees, state-of-the-art machines – ZELTWANGER has invested hugely in its future Tübingen site over the last two years. The engineering business division alone has a good 8,200 square meters more space available with the new production hall on Eisenbahnstraße. ZELTWANGER Maschinenbau is a manufacturing service provider with 170 employees based at the Tübingen site and specializes in the manufacture of highly complex prototypes, single parts, and small series, as well as the assembly of modules, stations, and complete machines. And all this with a very short lead time.

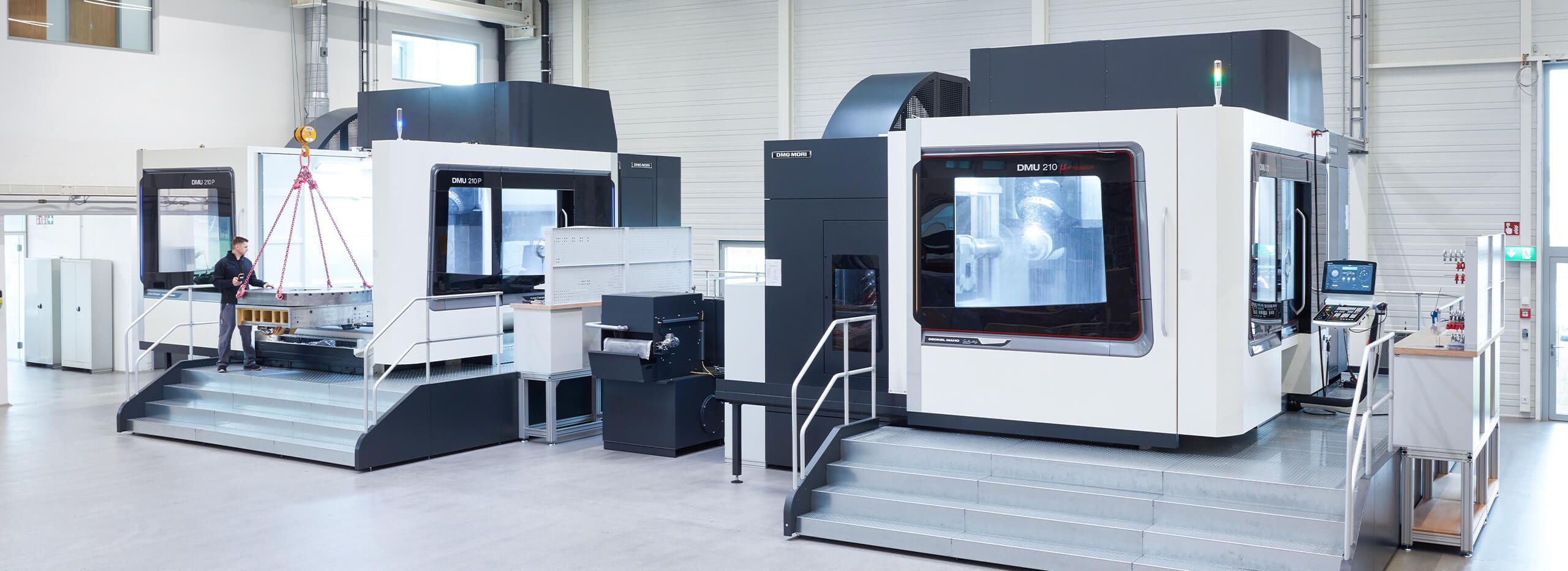

ZELTWANGER Maschinenbau has established a highly modern stock of machinery in its newly acquired production space over recent months, which is something that can only be matched by a handful of companies in Germany. For example, the impressive 50-ton, 5-axis high-precision milling machine DMU 210 μPrecision has been given a sister machine. Standing side by side, the two portal milling machines not only look impressive, they also stand out due to their state-of-the-art technology: “Our second DMU machine does not have a μ-precision option, but it does have an accuracy package that guarantees a position tolerance of eight μm across the entire work area. And it also processes parts of up to eight tons with maximum precision and an exceptional dynamic range,” says Andreas Wodarz, Managing Director of ZELTWANGER Maschinenbau, and adds: “Both large machines enable 5-axis simultaneous machining in one setup. The sophisticated, extensive cooling of all relevant machine components is crucial. The temperature stability achieved in this way ensures maximum component accuracy.”

ZELTWANGER is working on technologies for tomorrow and the day after tomorrow

Just over a year ago, ZELTWANGER invested millions in the first of the two high-end machines – the high-precision variant μ-Precision with positioning accuracy of up to four μm is one of a kind. So why did they make another one? “Shortly after commissioning in January 2018, the μ-Precision was already running in three-shift operation and there was no accompanying fall in demand for highly complex components,” says Wodarz. This is why, the decision was made in the second quarter of 2018 to invest in a DMU 210 P with an accuracy package. Since successful commissioning in January 2019, this machine has also been running in three-shift operation.

Highest precision when machining very large components – ZELTWANGER Maschinenbau specializes in small series and prototypes. This is of particular interest to sectors that are dealing with the technology of tomorrow: “We are one of the first companies that springs to mind when it comes to future technologies. Our components are good quality and when it comes to new innovations, we have the knowledge, experience, and the right drive to develop,” says Wodarz. At ZELTWANGER, we are working on technologies for tomorrow and the day after tomorrow – for products that do not currently exist on the market. The products of tomorrow need to be produced somehow. This requires components that do not exist yet. And the machines that can manufacture them.

The DMC 80 FDS: Three technologies combined in one machine – it hardly gets more precise than that

ZELTWANGER is working hard to realize the future visions of its customers with its highly modern stock of machinery. Alongside the two DMU 210, this involves another machine highlight: The DMC 80 FDS is a universal machining center that combines milling, turning, and grinding in one machine. “The integration of grinding technology into milling/turning technology is pioneering and facilitates excellent surface finish and dimensional quality. Execution of the grinding process in a single setup not only entails process reliability and increased efficiency, the grinding finish machining also ensures a perfect fit – it is hardly possible to be more compact and precise,” explains Wodarz.

6.2 million euros on state-of-the-art machines and tools – at ZELTWANGER Maschinenbau, we have everything we need to face the challenges of the future. The icing on the cake with the new acquisitions is a measuring machine from Zeiss that can even record extremely large components. “For prototypes in particular, this recording is essential for quality assurance and extremely important to our customers,” says Managing Director Wodarz. He also adds: “With our highly modern machinery, we meet all the requirements for manufacturing products that are ready for Industry 4.0. This is something that very few companies in Germany can claim.”

Press contact:

ZELTWANGER Maschinenbau GmbH

Andreas Wodarz

Eisenbahnstr. 158

72072 Tübingen

Germany

Phone +49 7071/3663 101

maschinenbau@zeltwanger.de

More articles

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de