LEAK TESTING FOR MEDICAL TECHNOLOGY

QUALITY ASSURANCE WITH INTEGRATED LEAK TESTING

Leak testing, which is part of manufacturing catheters, catheter balloons, luer connectors, dialyzers, IV bags, and respiratory gas filters in medical technology contexts, is a highly sensitive process with strict standards to meet.

From determining the lowest measurable leak rates and performing measuring instrument capability investigations to identifying required cycle times, we have developed a range of solutions with our finely honed expertise in leak testing. We have what it takes to support you from product and process development through high-volume production.

- Home

- Medical Technology

- Leak Testing

SMALL COMPONENTS

Because of their size, miniaturized valves made from silicone and other plastics are challenging to deal with in leak testing. Non-return valves, for instance, require not only leak testing but also opening pressure detection at minimum diameters.

Small component volumes

For applications involving our ZEDcore modular measuring unit, we have developed an external valve block that minimizes the volume on the device side – allowing even the smallest volumes to be tested efficiently.

Minimum permissible leakage rates

The entire ZED device family, which includes the ZEDbase+, comes with our modular ZEDcore measuring unit featuring highly sensitive sensor technology – allowing even the lowest leak rates to be detected reliably.

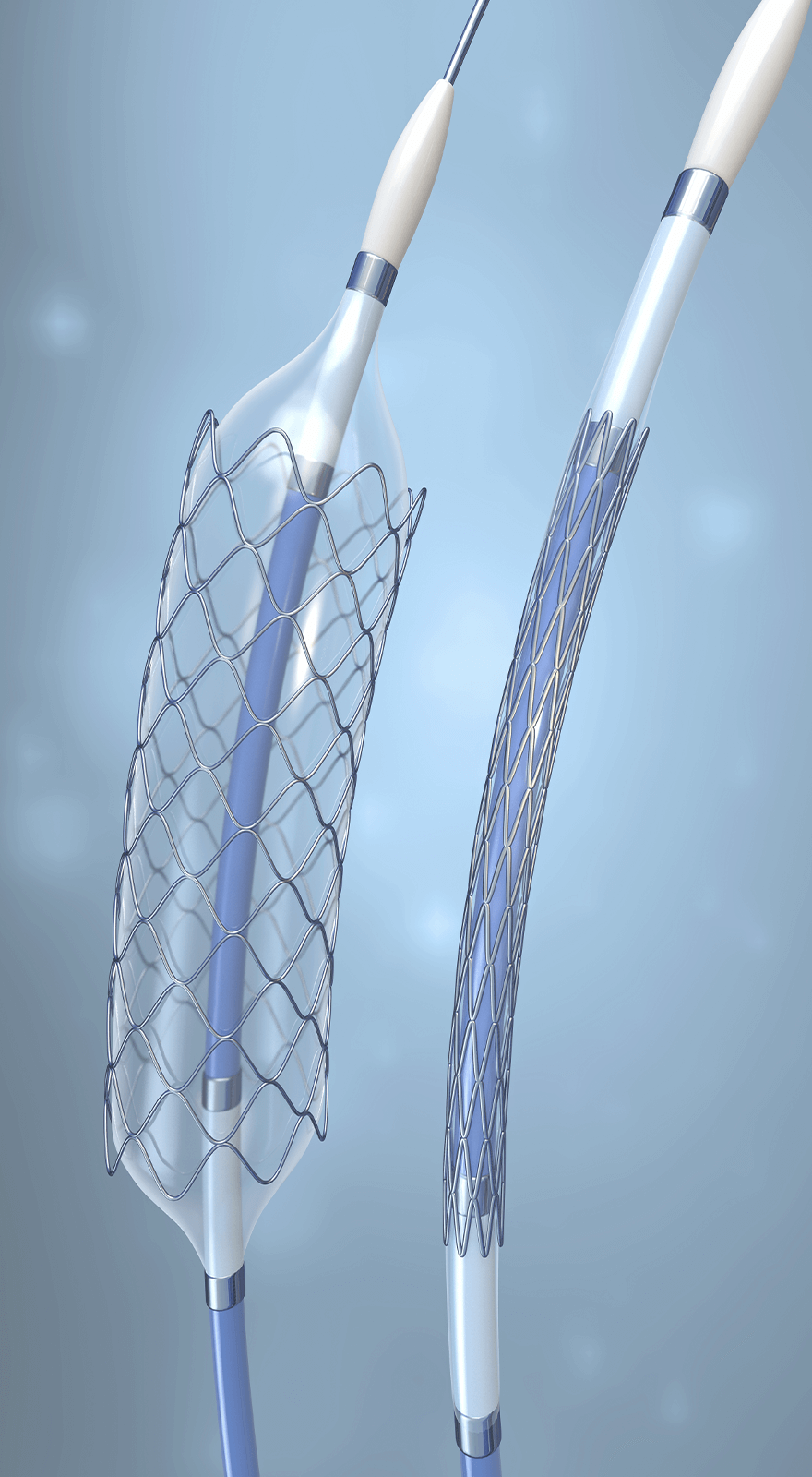

COMPLEX COMPONENTS

The structure and complexity of catheters make them challenging to deal with in leak testing. We test:

- Single-lumen, multi-lumen, and PTCA catheters: leak testing, flow testing, burst pressure testing

- Flushing systems: leak testing, flow testing

- Hose systems: leak testing, flow testing

Volume instability

We have made the testing process even better with a customized pre-filling process that stabilizes the volume during the measurement time.

Adaptation

Handling flexible parts such as catheters requires intelligent solutions. Take advantage of our experience in manual and automated adaptations.

LARGE COMPONENTS

Bioprocess bag testing requires a reliable method of detecting low leak rates at very large volumes.

Very large volumes (up to 3,000 liters)

We have developed a special test bench that accelerates the filling process. It has been designed in line with customer requirements for use in cleanroom class 7 environments according to EN ISO 14644-1.

Determining leak rates

We use special test leaks to simulate certain hole sizes between 10 μm and 250 μm.

SENSITIVE COMPONENTS

Our ZELTWANGER sensor technology is ideal for testing sensitive components such as respiratory gas filters.

Very low test pressure

Specialized high-precision sensor technology is essential for performing tests at very low levels of test pressure. This technology is included in the modular ZEDcore measuring unit, making it available for the entire family of devices to use.

LARGE NUMBER OF UNITS

Getting reliable results when performing quality assurance procedures on dialyzers and dialysis accessories requires high-precision sensor technology. A modular design allows this technology to be used with the entire family of devices, making it possible to cater to specific requirements.

Very short cycle times

Our multi-channel solutions – which include the ZEDflex – provide a flexible basis for optimizing test times in cases where testing processes are more complicated.

PUT YOUR PROCESS IN SAFE HANDS

Covering everything from leak testing and flow testing to burst pressure testing, our wide-ranging expertise and many years of experience allow us to help our medical technology customers develop a complete process solution. We specialize in:

- Manual adaptations

- Appropriate software and OPC UA interfaces

- Adapters

- Complex parts

- Automated solutions and systems

- Expert advice and outstanding service

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de