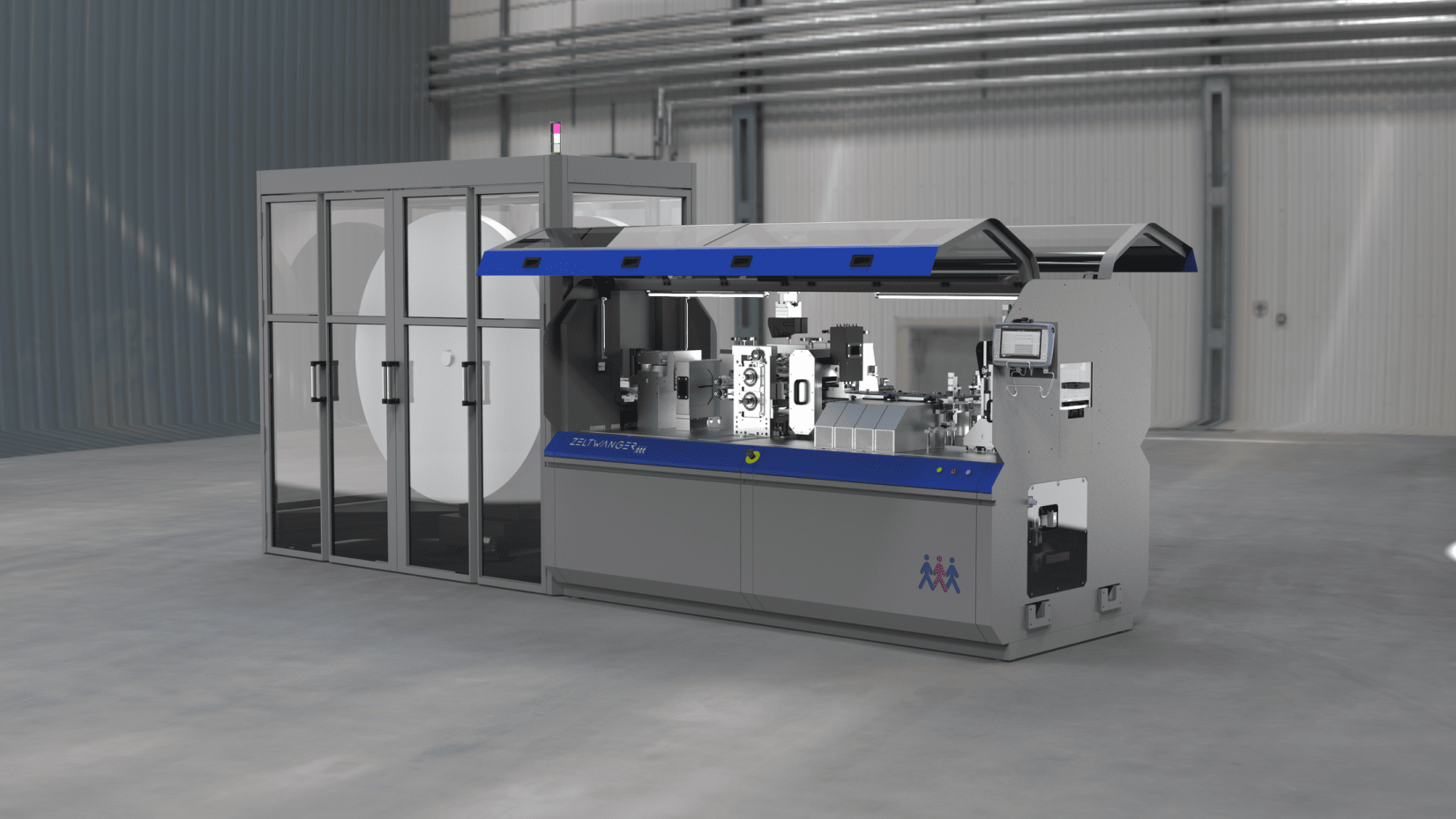

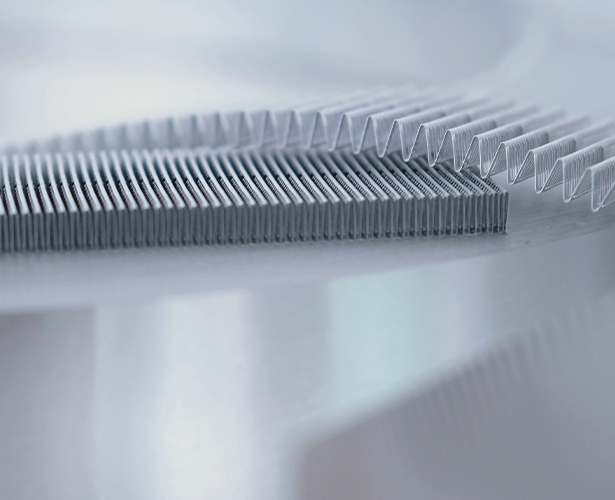

Efficiency and precision for lamella production

Rely on scalable precision systems that efficiently and reliably process even complex lamella geometries and high lamella densities. Technologically advanced – for future-proof heat exchanger production at the highest level.

User-friendly & automated

Automate your processes. Rely on maximum user-friendliness.

-

Everything digital. No manual handling:

Control all processes centrally via the HMI – intuitively, safely and efficiently -

Tool detected. Process secured:

NFC detects components immediately—ensuring fast access, safe processes and error-free work. -

Intelligent lubrication:

Oil consumption automatically adapts to speed and bandwidth—ensuring clean processes with optimal use of resources.

Efficient & powerful

Maximize your output – with a high number of cycles, short set-up times, and stable performance

-

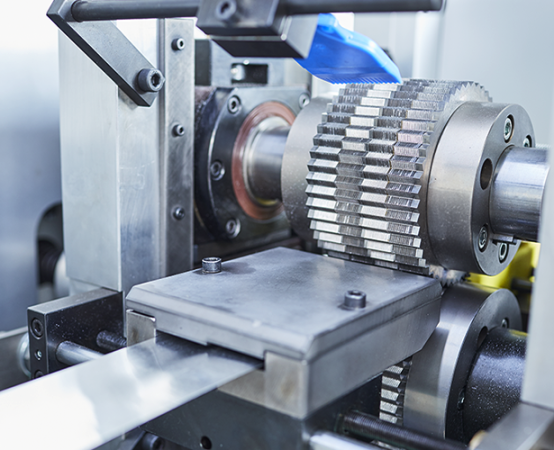

High-speed cutting:

Up to 180 cuts/min (single track) or 360/min (double) – with constant cutting quality and a maximum belt speed of 6.5 m/s. -

Tool-free conversion—ready in minutes:

Quick-release system, tool-free changeover and maintenance-free components reduce set-up time by up to 80%—for maximum flexibility and availability.

Precision & Quality

Ensure the highest quality. Measure, control and monitor automatically – in real time.

-

Cutting without length fluctuations:

The flying guillotine guarantees consistently precise cutting lengths. -

Quality 100% inline tested:

Inline height, density and Louver Angle Measurement System – maximum control for every part. -

Precise to the last detail:

± 0.05 mm belt guide at 6.5 m/s – fully automatically controlled. -

Constant slat height:

Belt force control keeps heights constant – even under changing conditions. -

Automated belt guidance:

± 5° belt path correction for perfect cutting quality.

Scalable & future-proof

Rely on a technology that adapts to your development.

-

Compact & integrated:

Up to 50% smaller space requirement thanks to integrated control cabinet. -

Flexible in every direction:

Automatic detection of the coil direction and manufacturer-independent tool holder. -

Versatile in terms of materials:

Suitable for aluminum, stainless steel, copper – flexible for all requirements. -

Modular and scalable machine concept:

Tailored to your production volumes and flexibly adaptable when production requirements change. -

Digital system information:

Tailored to your production volumes and flexibly adaptable when production requirements change.

-

All common fin types:

Ob Whether corrugated, flat, turbulator or oil cooler – everything is possible. -

Future-proof & retrofittable:

Open to new requirements – upgradeable for higher outputs and new products. -

Energy-efficient design:

Minimizes energy consumption while maintaining peak performance, reduces operating costs and supports sustainable production. -

Minimal changeover times:

Reduces downtimes and increases productivity through fast and efficient tool and product changes. -

Efficient and cost-saving oil lubrication:

Up to 70% less oil consumption and 95% less waste with optimal soldering quality thanks to precise, automatic oil application.

Service & support

Stay productive – with service that lasts. And technology that delivers.

-

Tooling from a single source:

Development, production and post-processing of your tools—all from a single source. -

Long-term support:

After-After-sales service and spare parts sustainably secure your investment.

LUBRICATION UNIT

FOR FIN MILLS

Manufacturer-independent, retrofit lubrication unit for precise minimum quantity lubrication of strip material.

-

double-sided lubrication

-

two adjustable atomizing nozzles

-

automatic adjustment to strip width and strip speed

-

mist-free operation without a pressurized tank

-

up to 70% lower oil consumption

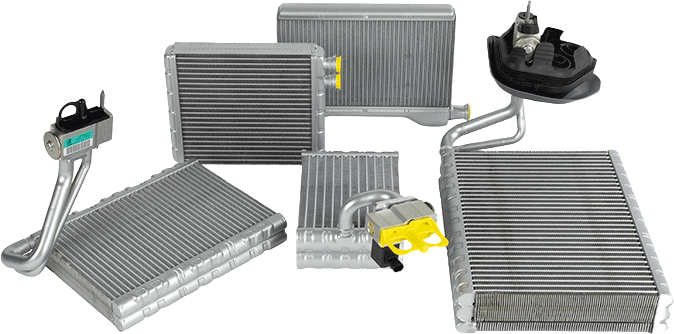

Typical applications

-

Low-temperature cooler

-

Condenser

-

Evaporator

-

Coolant cooler

-

Radiators

-

Heat pumps

-

Intercoolers

-

PTC heaters

All the information about the Fin Mill summarized for you:

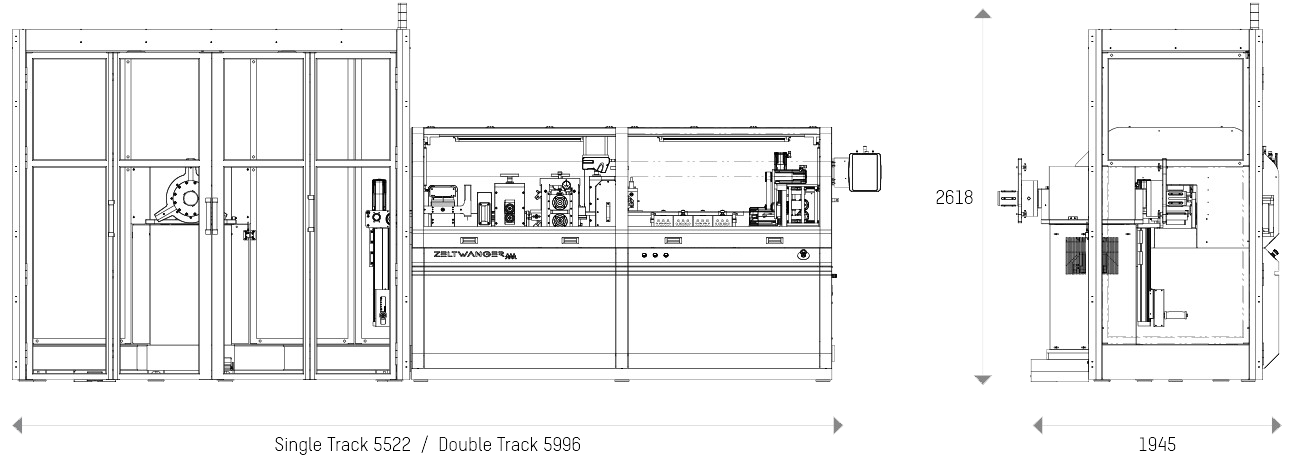

Technical data at a glance

| Layout | Single Track & Double Track |

| Fin type | Louver fins, flat fins, oil cooler fins, turbulator fins |

| Belt material | Aluminum, stainless steel, copper |

| Belt width | 10 mm – 110 mm |

| Fins/min. | 180 fins/min. (Single Track) / 360 fins/min. (Double Track) |

| Flat belt speed | Max. 6,5 m/s |

| Conversion | Max. 10 min. with a setter |

With strong partners for success

Are you working on a project in the field of thermal management or do you have questions about our products? Our experts will be happy to advise you – individually, practically, and in a solution-oriented manner. Whether product details, application possibilities or system solutions: We are here for you.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de